Category:

Needle Mat

EAS offers high quality E glass needle mat, ECR glass needle mat, high silica needle mat, carbonized needle mat.

Product description

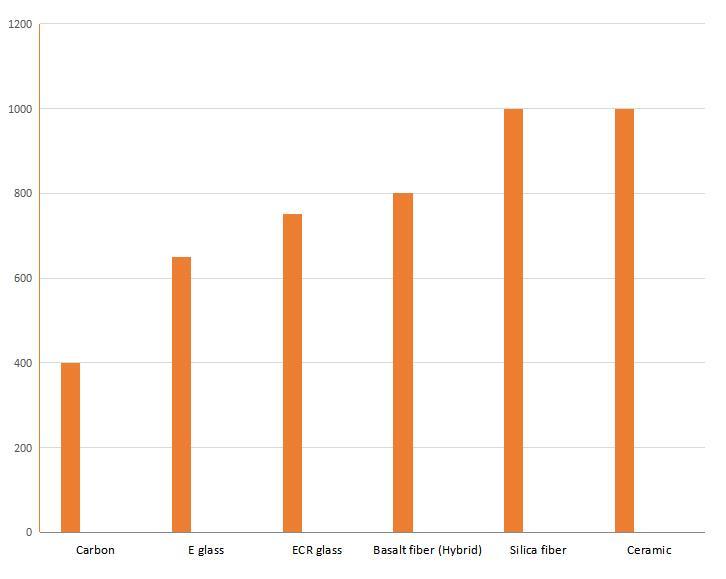

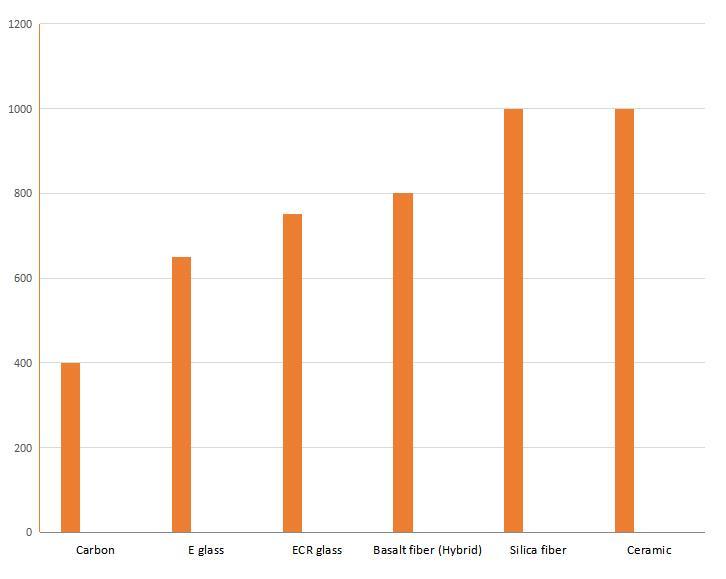

Needle mat is 100% mechanically bonded by E glass fiber, ECR glass fiber, S glass, Silica fiber, Basalt fiber, Carbon fiber. Needle mat is a great thermal insulation barrier. It offers non flammability, high temperature service, low thermal conductivity, low cost. Fiberglass needle mat has high temperature service, excellent acoustic insulation, non combustible, very low health hazard compared with mineral wool, glass wool etc.

E glass needle mat, ECR glass needle mat, Silica needle mat, Basalt needle mat can be further finished with PTFE imprgenated, aluminum foil lamination

Fiber diameter

E glass: 9-13um

ECR glass: 11-17um

Silica fiber: 6-9um

Density range

110-180kg/m3

Thickness range

3-50mm

Fiber option

|

Item |

Thickness, mm |

Density, g/m3 |

Area weight g/m2 |

Width, mm |

|

NMC-3(ECR) |

3 |

130 (120-180) |

400 |

1000~2000 |

|

NMC-6(ECR) |

6 |

130 (120-180) |

800 |

1000~2000 |

|

NMC-10(ECR) |

10 |

140 (120-180) |

1400 |

1000~2000 |

|

NMC-12(ECR) |

12 |

150 (120-180) |

1800 |

1000~2000 |

|

NMC-25(ECR) |

25 |

160 (120-180) |

4000 |

1000~2000 |

|

NMC-30(ECR) |

30 |

160 (120-180) |

4800 |

1000~2000 |

|

NMC-40(ECR) |

40 |

160 (120-180) |

6400 |

1000~2000 |

|

NMT-3 |

4 |

130 (130-160) |

390 |

1000~2000 |

|

NMT-6 |

6 |

130 (130-160) |

780 |

1000~2000 |

|

NMT-10 |

10 |

130 (130-160) |

1300 |

1000~2000 |

|

NMT-12 |

12 |

150 (130-160) |

1800 |

1000~2000 |

|

NMT-20 |

20 |

160 (140-160) |

3200 |

1000~2000 |

|

NMT-25 |

25 |

160 (140-160) |

4000 |

1000~2000 |

|

NMTC |

3-25 |

130-160 |

20%, 40%, 80% |

|

| NMP | 2-10 | 100-130 | Carbonized 60%-96% | |

Needle Mat, also known as Needle-Punched Mat or Needle-Felt Mat, is a versatile and high-quality material made from various fibers that are mechanically interlocked through a needle-punching process. It is renowned for its excellent thermal insulation, sound absorption, and filtration properties, making it suitable for a wide range of applications where these characteristics are required.

One of the key features of Needle Mat is its exceptional thermal insulation properties. It has a high density and thickness, which provide excellent resistance to heat transfer. Needle Mat is commonly used in industries such as construction, automotive, and aerospace, where thermal insulation is essential for energy efficiency and temperature control. It effectively minimizes heat loss or gain, reducing energy consumption and maintaining comfortable living or working environments.

Another significant advantage of Needle Mat is its excellent sound absorption capabilities. The intertwined fibers and dense structure of Needle Mat help to absorb and dampen sound waves, reducing noise levels and improving acoustic comfort. Needle Mat is widely used in applications such as soundproofing walls, floors, and ceilings in buildings, as well as in automotive and industrial machinery to reduce noise pollution.

Furthermore, Needle Mat offers excellent filtration properties. The dense and interconnected fibers create a porous structure that allows air or liquid to pass through while trapping and retaining unwanted particles, dust, or contaminants. Needle Mat is commonly used as a filtration medium in applications such as air filters, oil filters, and dust collectors in industries including HVAC, automotive, and manufacturing.

Moreover, Needle Mat is highly durable and resistant to wear and tear. The mechanical interlocking of fibers through the needle-punching process provides stability and strength to the mat, ensuring long-term performance even in demanding environments. Needle Mat is commonly used in applications that require durability, such as underlayment for carpets, padding for upholstery, and reinforcement for composites.

Additionally, Needle Mat is lightweight and flexible, making it easy to handle and install. Its flexibility allows it to conform to various shapes and surfaces, making it suitable for complex or irregular applications. Needle Mat can be easily cut, shaped, or molded to meet specific design requirements.

Furthermore, Needle Mat is often manufactured from recycled or eco-friendly materials, contributing to sustainability and environmental responsibility. It can be made from recycled fibers or natural fibers, reducing waste and minimizing the ecological footprint.

In summary, Needle Mat is a versatile and high-quality material known for its excellent thermal insulation, sound absorption, and filtration properties. Its applications range from thermal insulation in construction to soundproofing, filtration, and reinforcement in various industries. With its outstanding characteristics and versatility, Needle Mat continues to be a preferred choice in applications where thermal insulation, sound absorption, filtration, and environmental friendliness are crucial.

- Production Description

- Size&Packing

- Technical data

-

- Commodity name: Needle Mat

- Commodity ID: c1

EAS offers high quality E glass needle mat, ECR glass needle mat, high silica needle mat, carbonized needle mat.

Needle mat is 100% mechanically bonded by E glass fiber, ECR glass fiber, S glass, Silica fiber, Basalt fiber, Carbon fiber. Needle mat is a great thermal insulation barrier. It offers non flammability, high temperature service, low thermal conductivity, low cost. Fiberglass needle mat has high temperature service, excellent acoustic insulation, non combustible, very low health hazard compared with mineral wool, glass wool etc.

E glass needle mat, ECR glass needle mat, Silica needle mat, Basalt needle mat can be further finished with PTFE imprgenated, aluminum foil lamination

Fiber diameter

E glass: 9-13um

ECR glass: 11-17um

Silica fiber: 6-9um

Density range

110-180kg/m3

Thickness range

3-50mm

Fiber option

Item

Thickness, mm

Density, g/m3

Area weight

g/m2

Width, mm

NMC-3(ECR)

3

130 (120-180)

400

1000~2000

NMC-6(ECR)

6

130 (120-180)

800

1000~2000

NMC-10(ECR)

10

140 (120-180)

1400

1000~2000

NMC-12(ECR)

12

150 (120-180)

1800

1000~2000

NMC-25(ECR)

25

160 (120-180)

4000

1000~2000

NMC-30(ECR)

30

160 (120-180)

4800

1000~2000

NMC-40(ECR)

40

160 (120-180)

6400

1000~2000

NMT-3

4

130 (130-160)

390

1000~2000

NMT-6

6

130 (130-160)

780

1000~2000

NMT-10

10

130 (130-160)

1300

1000~2000

NMT-12

12

150 (130-160)

1800

1000~2000

NMT-20

20

160 (140-160)

3200

1000~2000

NMT-25

25

160 (140-160)

4000

1000~2000

NMTC

3-25

130-160

20%, 40%, 80%

NMP 2-10 100-130 Carbonized 60%-96% Needle Mat, also known as Needle-Punched Mat or Needle-Felt Mat, is a versatile and high-quality material made from various fibers that are mechanically interlocked through a needle-punching process. It is renowned for its excellent thermal insulation, sound absorption, and filtration properties, making it suitable for a wide range of applications where these characteristics are required.

One of the key features of Needle Mat is its exceptional thermal insulation properties. It has a high density and thickness, which provide excellent resistance to heat transfer. Needle Mat is commonly used in industries such as construction, automotive, and aerospace, where thermal insulation is essential for energy efficiency and temperature control. It effectively minimizes heat loss or gain, reducing energy consumption and maintaining comfortable living or working environments.

Another significant advantage of Needle Mat is its excellent sound absorption capabilities. The intertwined fibers and dense structure of Needle Mat help to absorb and dampen sound waves, reducing noise levels and improving acoustic comfort. Needle Mat is widely used in applications such as soundproofing walls, floors, and ceilings in buildings, as well as in automotive and industrial machinery to reduce noise pollution.

Furthermore, Needle Mat offers excellent filtration properties. The dense and interconnected fibers create a porous structure that allows air or liquid to pass through while trapping and retaining unwanted particles, dust, or contaminants. Needle Mat is commonly used as a filtration medium in applications such as air filters, oil filters, and dust collectors in industries including HVAC, automotive, and manufacturing.

Moreover, Needle Mat is highly durable and resistant to wear and tear. The mechanical interlocking of fibers through the needle-punching process provides stability and strength to the mat, ensuring long-term performance even in demanding environments. Needle Mat is commonly used in applications that require durability, such as underlayment for carpets, padding for upholstery, and reinforcement for composites.

Additionally, Needle Mat is lightweight and flexible, making it easy to handle and install. Its flexibility allows it to conform to various shapes and surfaces, making it suitable for complex or irregular applications. Needle Mat can be easily cut, shaped, or molded to meet specific design requirements.

Furthermore, Needle Mat is often manufactured from recycled or eco-friendly materials, contributing to sustainability and environmental responsibility. It can be made from recycled fibers or natural fibers, reducing waste and minimizing the ecological footprint.

In summary, Needle Mat is a versatile and high-quality material known for its excellent thermal insulation, sound absorption, and filtration properties. Its applications range from thermal insulation in construction to soundproofing, filtration, and reinforcement in various industries. With its outstanding characteristics and versatility, Needle Mat continues to be a preferred choice in applications where thermal insulation, sound absorption, filtration, and environmental friendliness are crucial.

Keywords:- E glass needle mat

- ECR glass needle mat

- Silica fiber needle mat

- carbon needle felt

-

PE flm, Polybag, Carton, Pallet

Roll diameter: 50-60mm

Width: 300mm-2000mm

Length: 5-40m -

Item

Thickness, mm

Density, g/m3

Area weight

g/m2

Width, mm

NMC-3(ECR)

3

130 (120-180)

400

1000~2000

NMC-6(ECR)

6

130 (120-180)

800

1000~2000

NMC-10(ECR)

10

140 (120-180)

1400

1000~2000

NMC-12(ECR)

12

150 (120-180)

1800

1000~2000

NMC-25(ECR)

25

160 (120-180)

4000

1000~2000

NMC-30(ECR)

30

160 (120-180)

4800

1000~2000

NMC-40(ECR)

40

160 (120-180)

6400

1000~2000

NMT-3

4

130 (130-160)

390

1000~2000

NMT-6

6

130 (130-160)

780

1000~2000

NMT-10

10

130 (130-160)

1300

1000~2000

NMT-12

12

150 (130-160)

1800

1000~2000

NMT-20

20

160 (140-160)

3200

1000~2000

NMT-25

25

160 (140-160)

4000

1000~2000

NMTC

3-25

130-160

20%, 40%, 80%

NMP 2-10 100-130 Carbonized 60%-96%

Keyword:

E glass needle mat

ECR glass needle mat

Silica fiber needle mat

carbon needle felt

Next

Market and application

Product inquiry

* is required! You can ask any questions in the company, including products. Please fill in the correct contact information so that we can reply to you in time!