Solutions

Fireproof

Fireproof is a board range of topic. Fireproof solution is divided into active fireproof and passive fireproof. Active fireproof can be understood as extingish fire that is widely used for fire blanket.More often, fiberglass materials are used for passive fireproof application. Fiberglass materials is a mineral material an incombustibility. It provides permanent fireproof and high temperature resistance.

|

Cooking fire |

320℃ |

|

Charcoal fire |

750-1200℃ |

|

Natural gas |

900-1500℃ |

|

Wood fire |

600-1027℃ |

|

Pool fire (Hydrocarbon) |

1100℃ (within 5 mins) |

|

Jet fire (Hydrocarbon) |

1100℃ (within 5 mins) |

|

Building fire |

600-1100℃ |

Fiber is property. Different glass fiber type offers different properties. Fiberglass is a high temperature and fireproof material working temperature ranging from 550℃ to 1000℃.Fiberglass material can be impoved properties like fire, smoke, weather, waterproof, high temperature, weave setting, thermal reflection through lamination, coating and other finish. Flame retarded is a fireproof standarded.There are many flame retarded class according to various standard like BS476, EN13501-1, GB/T8624

Materials temperature:

|

Material |

℃ |

℉ |

Material |

℃ |

℉ |

|

PTFE |

260 |

500 |

Para-aramid |

260-400 |

500-750 |

|

FEP film |

220 |

428 |

OPAN |

400-1000 |

750-1800 |

|

PFA film |

260 |

500 |

C glass |

550-750 |

1000-1380 |

|

Silicone |

260 |

500 |

E glass |

550-850 |

1000-1560 |

|

Silicone ceramic |

1000-1650 |

1800-3000 |

ECR glass |

600 |

1100 |

|

Silicone intumescent |

1000-1650 |

1800-3000 |

S glass |

800 |

1470 |

|

Silicone adhesive |

260 |

500 |

Basalt |

650 |

1200 |

|

PU(Polyurethane) |

150 |

300 |

Silica (Leached E glass) |

800 |

1470 |

|

Acrylic |

150 |

300 |

High Silica (96% SiO2) |

1000 |

1800 |

|

Acrylic solvent based |

150-200 |

300-390 |

Quartz |

1050 |

1920 |

|

Acrylic water based |

200-240 |

390-460 |

Ceramic |

1000-1200 |

1800-2200 |

|

Aluminum foil |

600 |

1100 |

|

|

|

|

Steel (wire,foil, thread) |

800-1100 |

1470-2000 |

|

|

|

|

PVC |

120 |

240 |

|

|

|

|

Hypalon |

120 |

240 |

|

|

|

|

Viton |

260 |

500 |

|

|

|

|

PET film |

200 |

390 |

|

|

|

|

Vermiculite |

700-1000 |

1300-1800 |

|

|

|

|

Graphite (with matrix) |

650-1000 |

1200-1800 |

|

|

|

|

HT finish |

750 |

1380 |

|

|

|

(Above data is typical material used temperature. There should also refer temperature: Soften point, Melt point; Short time working, long time working. The real working temperature is very related about the specific application as well as the textile state)

Fire&smoke curtain prevents fire or smoke spread aimed to avoid or reduce fire disaster risk. The fire&smoke curtain usually serve for buldings to prevent fire spread, to limit initial fire development, to protect escape rountes. Control the fire 30mins-60mins-120mins-180mins-240mins with E, EI, EW styles curtains. EAS provide high quality fiberglass fabric for the fire and smoke. curtain solutions meet request of EN13501-1 A2.

Typical used: PC400, PC300R, PC400R, SC400, ALPC400R, NMT-6, RB1000, PT600

Welding&Fire blanket is a big material comsumption market. Fiberglass material is widely used for welding sparks protection, curtains, blanket, pad protection temperature 500-1200℃. This welding blanket can be in sewn blanket or in fiberglass cloth rolls. All EAS's fabrics can be used as welding fire blanket.

Typical and widely used:

Loomstate: C400ECO, A2025, A3200

Caramelized: HT800, HA2025, HA30

Finished fabric: T600, T1100, PC400, BA2025, BC2523, BC800C, BC600C

|

Loomstate fabric |

Itching, uneasy cut |

Low cost, No fire and low smoke release |

|

Caramelized/Heat treated fabric |

Itching, uneasy cut |

Low cost, No fire and smoke free, softer |

|

Acrylic, Silicone, PU, HT coated fabric |

Not so itching, easy cut, higher extreme temperature point |

Higher cost, medium fire and smoke release (Controllable) |

Fire blanket is fire extinguish blanket typically kitchen fire blanket meet standard EN1869. Made by typical C400ECO and SC400 fabric. This sewn fire blanket can meet various countries standard like EU, UK, USA,Australia, Canada,Korea etc. EAS can provide both fire blanket fiberglass fabric and finished sewn blanket.

Typical used: C400ECO, SC400

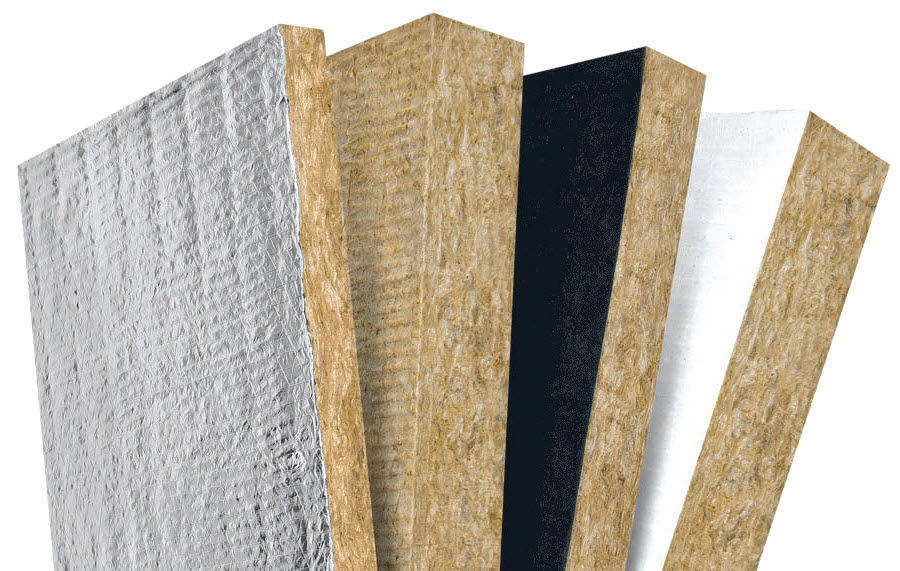

Thermal facing is a fireproof material facing to the insulation barrier surface that make the insulation layer thermal reflection, dust free,water vapour barrier meet EN13501-1 A2

Typical used: BC140, BC200, BC400, ALC200, ALC400, ALC600C, RM60, ALFM