Technology & Research

Yarn

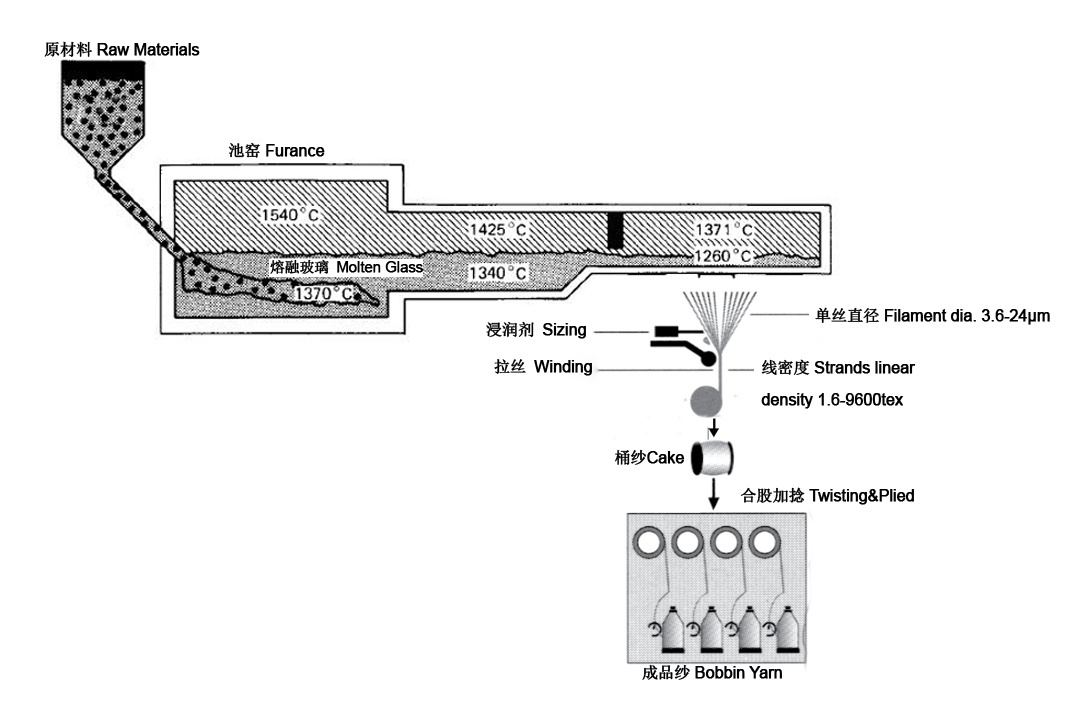

Glass fiber process

Glass melts are made by fusing silica with minerals containing specific oxides. After the fusion, the molten materials are cooled quickly to prevent crystallization, and glass fibers are formed through a specific process, it’s also called glass fibration.

Continuous glass fibers are generally made through direct drawing process. Molten glass is extruded and drawn through a platinum-alloy drain plate which contains thousands of individual holes, the hole diameter is from 0.793 to 3.175 mm. The fibers passing through holes will be quickly drawn into monofilaments and solidified. The diameter of glass fiber usually is from 3-20um. After that, glass filament fiber will be assembled to fiberglass yarn and wound to tube through winding machine.

Sizing

Glass filament fiber is abrasive between each other, which will cause the loss of glass fiber strength. In order to minimize this kind loss, there will be “glue” coating or adhesive material used before glass fiber strands gathering, it’s also known as sizing process. Sizing is good for lubrication, protection and coupling. And the sizing coating is temporary, it can be removed by heat treatment. Besides, sizing is also good for further processing and treatment, it makes glass fiber better compatibility with resin substrate and interface chemical adsorption.

Glass fiber type are classified with different chemical composition for specific application. There are E glass, C glass, S glass, M glass, A glass, D glass. Each glass type imparts the fiber special features. And E glass is the most common one.

|

Letter Designation |

Property |

|

E, Electrical |

Low electrical conductivity |

|

C, Chemical |

High chemical durability |

|

S, Strength |

High strength |

|

M, Modulus |

High stiffness |

|

A, Alkali |

High alkali or soda lime glass |

|

D, Dielectric |

Low dielectric constant |

| Property | S glass | E glass | ECR glass | C glass | AR glass |

| Density, g/m3 | 2.54 | 2.58 | 2.72 | 2.52 | 2.70 |

| Softening point, oC | 1056 | 846 | 882 | 750 | 773 |

| Tensile strength, MPa | |||||

| 23oC | 4800 | 3440 | 3600 | 3310 | 3250 |

| 400oC | 4420 | 2620 | 2150 | 1500 | -- |

| 550oC | 2410 | 1680 | 1680 | -- | -- |

| Yong’s modulus, GPa | |||||

| 23oC | 86.9 | 72.5 | 80.5 | 68.5 | 73.5 |

| 550oC | 88.9 | 81.5 | 81.5 | ||

| Elongation, % | 5.7 | 4.8 | 4.8 | 4.8 | 4.8 |