Solutions

High temperature

High temperature proetction is different with fire protection. High temperature protection usually solve temperature insulation range 200-1200C degree while fire usually range 600-3000C degree and fire temperature is unstable and short time. For high temperature protection, we are more foucsing on its long time working temperature service to cool the temperature down or keep a energy saving.

|

Material |

℃ |

℉ |

Material |

℃ |

℉ |

|

PTFE |

260 |

500 |

Para-aramid |

260-400 |

500-750 |

|

FEP film |

220 |

428 |

OPAN |

400-1000 |

750-1800 |

|

PFA film |

260 |

500 |

C glass |

550-750 |

1000-1380 |

|

Silicone |

260 |

500 |

E glass |

550-850 |

1000-1560 |

|

Silicone ceramic |

1000-1650 |

1800-3000 |

ECR glass |

600 |

1100 |

|

Silicone intumescent |

1000-1650 |

1800-3000 |

S glass |

800 |

1470 |

|

Silicone adhesive |

260 |

500 |

Basalt |

650 |

1200 |

|

PU(Polyurethane) |

150 |

300 |

Silica (Leached E glass) |

800 |

1470 |

|

Acrylic |

150 |

300 |

High Silica (96% SiO2) |

1000 |

1800 |

|

Acrylic solvent based |

150-200 |

300-390 |

Quartz |

1050 |

1920 |

|

Acrylic water based |

200-240 |

390-460 |

Ceramic |

1000-1200 |

1800-2200 |

|

Aluminum foil |

600 |

1100 |

|

|

|

|

Steel (wire,foil, thread) |

800-1100 |

1470-2000 |

|

|

|

|

PVC |

120 |

240 |

|

|

|

|

Hypalon |

120 |

240 |

|

|

|

|

Viton |

260 |

500 |

|

|

|

|

PET film |

200 |

390 |

|

|

|

|

Vermiculite |

700-1000 |

1300-1800 |

|

|

|

|

Graphite (with matrix) |

650-1000 |

1200-1800 |

|

|

|

|

HT finish |

750 |

1380 |

|

|

|

(Above data is typical material used temperature. There should also refer temperature: Soften point, Melt point; Short time working, long time working. The real working temperature is very related about the specific application as well as the textile state)

High temperature thermal sealing are often used in the industrial gasketing, packing,sealing wrapping for boiler,wick,oven door, metal catsing seals, fabric epxansion joint 300-1000℃. EAS produces fiberglass, silica and ceramic textiles by rope, tape, sleeve.

Packing, sealing

Typical used: Fiberglass braided rope, Fiberglass tape, Ceramic rope, Ceramic rape, ceramic cloth

|

Rope |

Braided |

Round, Square, Retangle |

Fiberglass, Silica, Ceramic |

Color dyed

|

|

Knitted |

Round, With core |

Fiberglass |

||

|

Twisted |

Round |

Fiberglass, Silica, Ceramic |

||

|

Tape |

Woven |

Plain, Twill, Ladder |

Fiberglass, Basalt, Ceramic, Silica |

Color dyed

|

|

Knitted |

- |

Fiberglass |

||

|

Slit |

- |

Fiberglass, silica |

||

|

Sleeve |

Braided |

- |

Fiberglass, Basalt, Ceramic, Silica |

Silicone coated |

Except high temperature textile, the non woven needle mat provide high efficient thermal insulation, sound insulation proerties function with very low thermal conduvtity, acoustic sound insulation. Needle mat is a 100% mechanically bond npn woven felt by E glass fiber, ECR glass fiber, Basalt fiber, OPAN fiber, Silica fiber and so on. As a thermal insulation barrier layer, It provides a high insulation efficiency and low cost insulation solution.

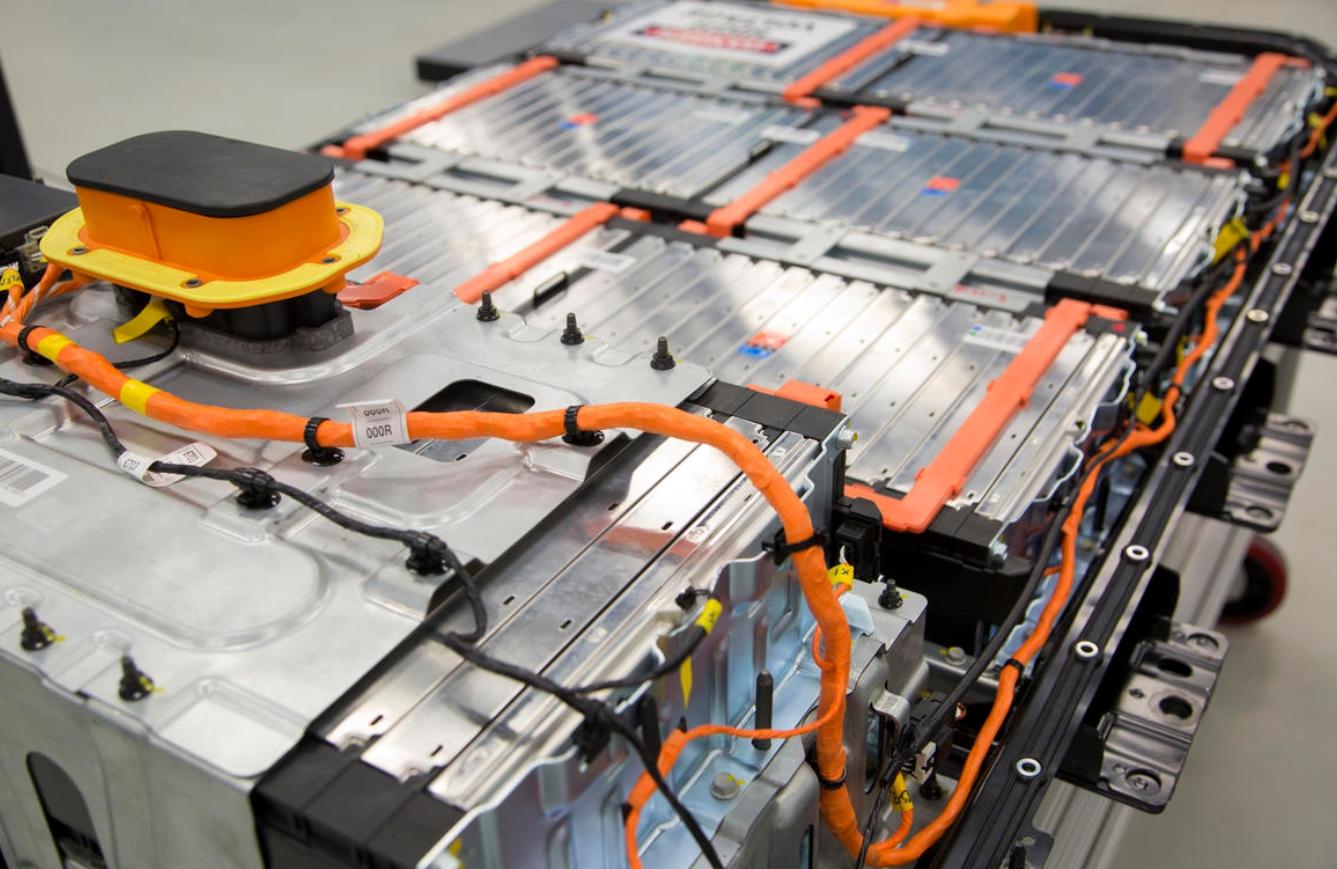

After composite with aerogel, the aerogel blanket can maximize its thermal insulation properties and keep still low thickness.It is an ideal solution for insulation in the military, EV lithium-ion battery. Fumed silica can exhibits a superb extremely high temperature insulation at 400-800℃.

Typical used: E glass needle mat, Silica needle mat, Aerogel blanket, Hinsuflex

Removable Insulation is a sewn multiple layer insulation blanket also called jacket, mattress,cover.Typically the removable insulation cover is sewn by cold layer, insulation layer and hot layer. It is a very convenient components for indoor and outdoor plants. It protect the plant from water, fire, oil, chemicals, high temperature, engery waste, freeze, noise and more.Materials are certified with IMO Part 1, IMO Part 5, RoSH, REACH,NFP 92-507 M1, NFPA701.

Materials are choosed according to insulation goal:

Passive fire protection UL1709, ISO22899-1, BS476-20&22

Energy saving

Hot insulation

Noise insulation

Cold insulation

Typical used: SC200, SC260, SC400, FC400, ALC400, ST600, SC400R, NMC, NMT, HA2025, T600, VT600, KT1000R

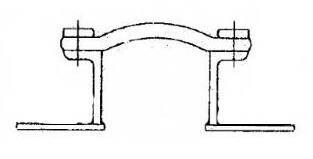

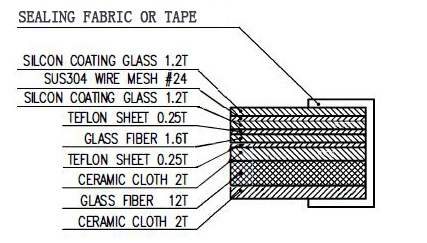

Fabric expansion joint is a flexible compensator system function as damper of high temperature, high chemical corrosion, high pressure vapor and gas flow pipes.

Offering materials solution for multi-layers fabric epxansion joint range high temperature to low temperature, high compression to low compression, wet to dry.

Typical used: SC1100, SC600, SC800, SC1600, SA30, FC200, FFM-3, HTA35R, PA35R, PA30, PA2025, VC800, HP-1, A6000, A6000R, A4000, NMC-6.