Texturized Yarn

EAS offers high temperature textile grade E glass texturized/volumized yarn 136tex, 272tex, 430tex, 600tex, 800tex, 1000tex, 1200tex, 2400tex with starch and silane yarn. Colored fiberglass yarn can also be offered.

Product description

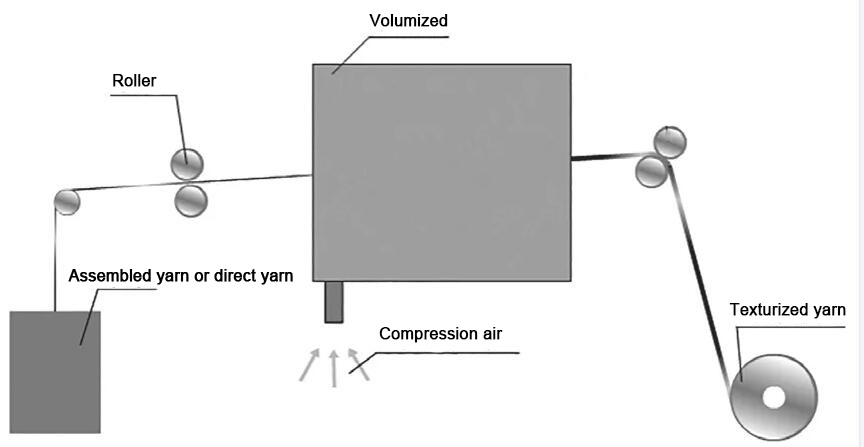

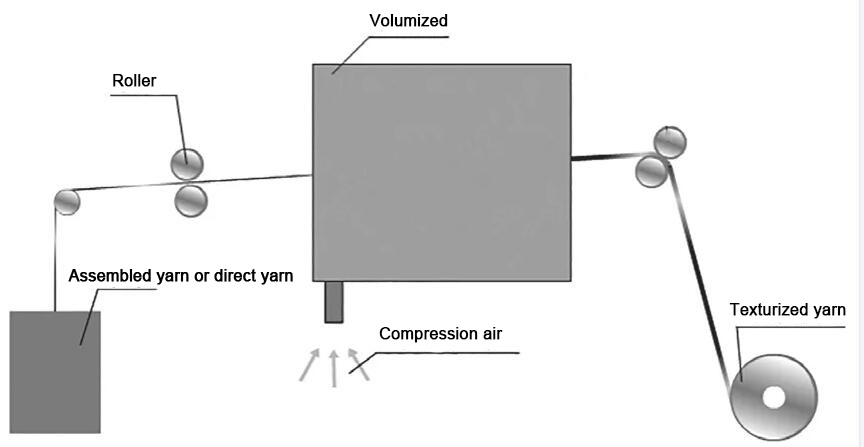

Texturized yarn is made from plied raw C glass, E glass, ECR glass fiberglass yarn, fiberglass roving, basalt yarn or basalt roving through compression air blow and make the fiber yarns bulied. After texturized, the yarn is volumized with soft, fluffy. The texturized has good performance of high temperature resistance, acoustic insulation, air permeability, fast wetting out. Texturized fiberglass yarn can be plied and twisted, composite with stainless steel wire, copper wire etc.

Identification

- ET9 430 Y1

- E: E glass

- T: Texturized

- 9: Fiber diameter

- 430: Tex number

- Y1: Sizing

Fiber Type

E glass, C glass, ECR glass, S glass, Basalt

Texturized Shape Type

Spiral, Plain (Direct yarn, assembled yarn), ATY (Air Texturized Yarn)

Special composition

Stainless steel wire twisted, Copper wire twisted, Acrylic&aramid yarn twisted

Tex number

136-9600tex

Sizing type

Starch, Silane, Starch&Silane

Fiber diameter

6um, 9um, 11um, 13um, 17um

| Item | Glass Type | Filament diameter,um | Sizing type | Moisture content, % | Liner density, tex |

| ET6-500 | E | 6 | Starch | 0.15 | 500 |

| ET6-650 | E | 6 | Starch | 0.15 | 650 |

| ET6-800 | E | 6 | Starch | 0.15 | 800 |

| ET6-1250 | E | 6 | Starch | 0.15 | 1250 |

| ET9-430 | E | 9 | Starch | 0.15 | 430 |

| ET9-550 | E | 9 | Starch | 0.15 | 550 |

| ET9-820 | E | 9 | Starch | 0.15 | 820 |

| ET9-1000 | E | 9 | Starch | 0.15 | 1000 |

| ET9-1250 | E | 9 | Starch | 0.15 | 1250 |

| ET9-1400 | E | 9 | Starch | 0.15 | 1400 |

| ET9-1800 | E | 9 | Starch | 0.15 | 1800 |

| ET9-2200 | E | 9 | Starch | 0.15 | 2200 |

| ET9-2400 | E | 9 | Starch | 0.15 | 2400 |

| ET6-285 | E | 6 | Starch | 0.15 | 285 |

| ET17-2400 | E/ECR | 17 | Silane | 0.15 | 2400 |

| ET17-5000 | E/ECR | 17 | Silane | 0.15 | 5000 |

Texturized Yarn is a specialized type of yarn that has been processed to create a textured or crimped appearance. This unique texture gives the yarn enhanced stretchability, bulkiness, and insulation properties, making it ideal for a wide range of applications.

One of the key features of Texturized Yarn is its increased elasticity. The texturizing process introduces irregularities into the yarn structure, creating loops, curls, or coils along its length. This imparted stretchiness allows the yarn to elongate and recover its original shape, making it suitable for applications that require flexibility and resilience. It is commonly used in the textile industry for manufacturing fabrics with stretch and recovery properties, such as sportswear, activewear, and elastic bands.

The texturized appearance of the yarn also adds bulkiness and loftiness to fabrics. This can provide improved insulation and thermal regulation properties, making it suitable for applications in cold weather conditions. Texturized Yarn is often used in the production of winter clothing items like sweaters, jackets, and thermal undergarments, where warmth and comfort are essential.

Another advantage of Texturized Yarn is its ability to trap air within its textured structure. This trapped air acts as an insulating layer, enhancing the thermal properties of fabrics made from this yarn. As a result, it is commonly used in the manufacturing of blankets, upholstery, and home textiles where insulation and comfort are desired.

Additionally, Texturized Yarn offers excellent moisture-wicking capabilities. The textured surface of the yarn creates tiny gaps or spaces that allow for better airflow and moisture absorption. This feature makes it suitable for applications in sportswear and outdoor gear, as it helps to draw sweat away from the skin and keep the wearer dry and comfortable.

The versatility of Texturized Yarn extends beyond the textile industry. It is also widely used in the production of ropes, cords, and webbing. The texturized structure of the yarn enhances its grip and friction properties, making it ideal for applications that require secure and reliable fastening, such as in camping equipment, luggage, and safety harnesses.

Furthermore, Texturized Yarn is available in various materials, including polyester, nylon, and acrylic, offering different levels of strength, durability, and performance characteristics to suit specific application requirements.

In summary, Texturized Yarn is a specialized yarn that undergoes a texturizing process to create a crimped or textured appearance. It offers increased elasticity, bulkiness, and insulation properties, making it suitable for a wide range of applications in the textile, outdoor, and industrial sectors. Whether it is used in fabrics for sportswear, winter clothing, or ropes and cords for various purposes, Texturized Yarn provides enhanced performance and comfort due to its unique texture and characteristics.

- Production Description

- Size&Packing

- Technical data

-

- Commodity name: Texturized Yarn

- Commodity ID: a2

EAS offers high temperature textile grade E glass texturized/volumized yarn 136tex, 272tex, 430tex, 600tex, 800tex, 1000tex, 1200tex, 2400tex with starch and silane yarn. Colored fiberglass yarn can also be offered.

Texturized yarn is made from plied raw C glass, E glass, ECR glass fiberglass yarn, fiberglass roving, basalt yarn or basalt roving through compression air blow and make the fiber yarns bulied. After texturized, the yarn is volumized with soft, fluffy. The texturized has good performance of high temperature resistance, acoustic insulation, air permeability, fast wetting out. Texturized fiberglass yarn can be plied and twisted, composite with stainless steel wire, copper wire etc.

Identification- ET9 430 Y1

- E: E glass

- T: Texturized

- 9: Fiber diameter

- 430: Tex number

- Y1: Sizing

Fiber Type

E glass, C glass, ECR glass, S glass, Basalt

Texturized Shape Type

Spiral, Plain (Direct yarn, assembled yarn), ATY (Air Texturized Yarn)

Special composition

Stainless steel wire twisted, Copper wire twisted, Acrylic&aramid yarn twisted

Tex number

136-9600tex

Sizing type

Starch, Silane, Starch&Silane

Fiber diameter

6um, 9um, 11um, 13um, 17um

Item Glass Type Filament diameter,um Sizing type Moisture content, % Liner density, tex ET6-500 E 6 Starch 0.15 500 ET6-650 E 6 Starch 0.15 650 ET6-800 E 6 Starch 0.15 800 ET6-1250 E 6 Starch 0.15 1250 ET9-430 E 9 Starch 0.15 430 ET9-550 E 9 Starch 0.15 550 ET9-820 E 9 Starch 0.15 820 ET9-1000 E 9 Starch 0.15 1000 ET9-1250 E 9 Starch 0.15 1250 ET9-1400 E 9 Starch 0.15 1400 ET9-1800 E 9 Starch 0.15 1800 ET9-2200 E 9 Starch 0.15 2200 ET9-2400 E 9 Starch 0.15 2400 ET6-285 E 6 Starch 0.15 285 ET17-2400 E/ECR 17 Silane 0.15 2400 ET17-5000 E/ECR 17 Silane 0.15 5000 Texturized Yarn is a specialized type of yarn that has been processed to create a textured or crimped appearance. This unique texture gives the yarn enhanced stretchability, bulkiness, and insulation properties, making it ideal for a wide range of applications.

One of the key features of Texturized Yarn is its increased elasticity. The texturizing process introduces irregularities into the yarn structure, creating loops, curls, or coils along its length. This imparted stretchiness allows the yarn to elongate and recover its original shape, making it suitable for applications that require flexibility and resilience. It is commonly used in the textile industry for manufacturing fabrics with stretch and recovery properties, such as sportswear, activewear, and elastic bands.

The texturized appearance of the yarn also adds bulkiness and loftiness to fabrics. This can provide improved insulation and thermal regulation properties, making it suitable for applications in cold weather conditions. Texturized Yarn is often used in the production of winter clothing items like sweaters, jackets, and thermal undergarments, where warmth and comfort are essential.

Another advantage of Texturized Yarn is its ability to trap air within its textured structure. This trapped air acts as an insulating layer, enhancing the thermal properties of fabrics made from this yarn. As a result, it is commonly used in the manufacturing of blankets, upholstery, and home textiles where insulation and comfort are desired.

Additionally, Texturized Yarn offers excellent moisture-wicking capabilities. The textured surface of the yarn creates tiny gaps or spaces that allow for better airflow and moisture absorption. This feature makes it suitable for applications in sportswear and outdoor gear, as it helps to draw sweat away from the skin and keep the wearer dry and comfortable.

The versatility of Texturized Yarn extends beyond the textile industry. It is also widely used in the production of ropes, cords, and webbing. The texturized structure of the yarn enhances its grip and friction properties, making it ideal for applications that require secure and reliable fastening, such as in camping equipment, luggage, and safety harnesses.

Furthermore, Texturized Yarn is available in various materials, including polyester, nylon, and acrylic, offering different levels of strength, durability, and performance characteristics to suit specific application requirements.

In summary, Texturized Yarn is a specialized yarn that undergoes a texturizing process to create a crimped or textured appearance. It offers increased elasticity, bulkiness, and insulation properties, making it suitable for a wide range of applications in the textile, outdoor, and industrial sectors. Whether it is used in fabrics for sportswear, winter clothing, or ropes and cords for various purposes, Texturized Yarn provides enhanced performance and comfort due to its unique texture and characteristics.

Keywords:- Fiberglass texturized yarn

- E glass texturized yarn

- Volumized glass yarn

- Fiberglass bulky yarn

-

Bobbin weight: 5-8KG

-

Item Glass Type Filament diameter,um Sizing type Moisture content, % Liner density, tex ET6-500 E 6 Starch 0.15 500 ET6-650 E 6 Starch 0.15 650 ET6-800 E 6 Starch 0.15 800 ET6-1250 E 6 Starch 0.15 1250 ET9-430 E 9 Starch 0.15 430 ET9-550 E 9 Starch 0.15 550 ET9-820 E 9 Starch 0.15 820 ET9-1000 E 9 Starch 0.15 1000 ET9-1250 E 9 Starch 0.15 1250 ET9-1400 E 9 Starch 0.15 1400 ET9-1800 E 9 Starch 0.15 1800 ET9-2200 E 9 Starch 0.15 2200 ET9-2400 E 9 Starch 0.15 2400 ET6-285 E 6 Starch 0.15 285 ET17-2400 E/ECR 17 Silane 0.15 2400 ET17-5000 E/ECR 17 Silane 0.15 5000

Keyword:

Fiberglass texturized yarn

E glass texturized yarn

Volumized glass yarn

Fiberglass bulky yarn

Previous

Next

Market and application

Product inquiry

* is required! You can ask any questions in the company, including products. Please fill in the correct contact information so that we can reply to you in time!