Technology & Research

Weaving

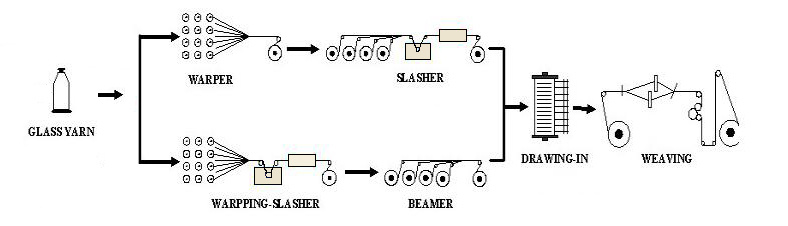

Beaming: make the glass fiber yarn passing through a carding and warping process, then wind on the warp beam for sizing.

Rebeaming: Put the finished warp on the loom, and then throw the weft, interweave warp and weft into loomstate fiberglass fabric

Heat clean: put the glass fiber fabric into oven dryer, and burn the organic material such as size on the fabric surface to 0.5-1.6% through high temperature

Postpone finish: make treatment on fabric surface, such as coating, film laminating

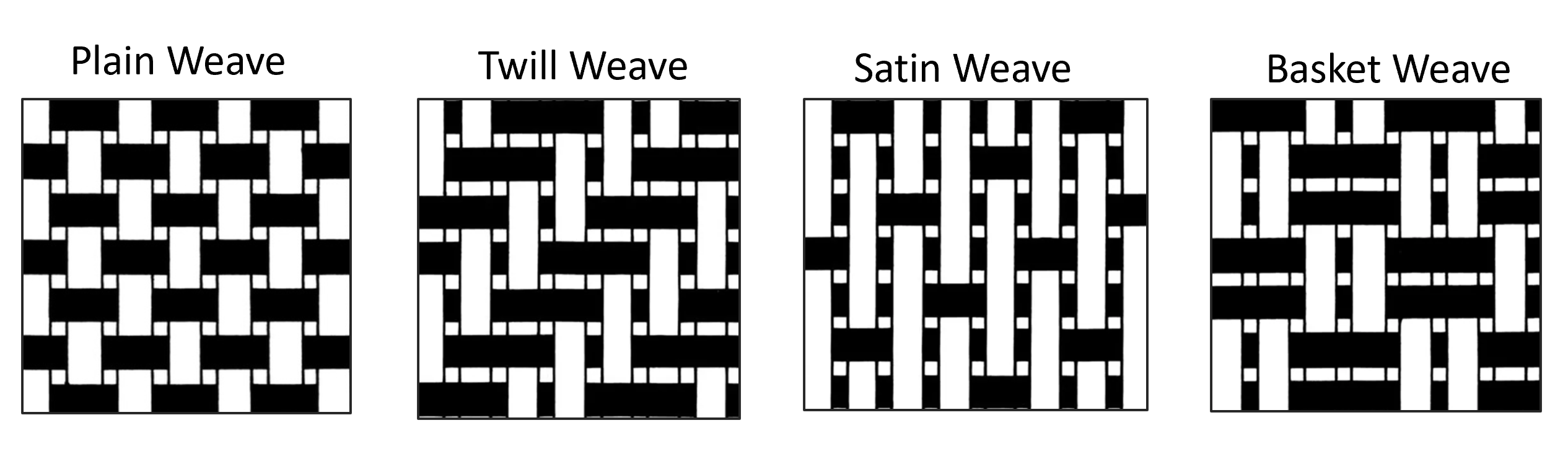

Typical weave pattern:

Loomstate fiberglass fabric is just weaved from looms (woven machine) without any finish.